Data-driven Reparameterization for the Structural Optimization of Ship Hulls

In the shipbuilding industry, designers often have to optimize innovative and complex ship designs with expensive computer simulations that validate structural safety according to established regulations. The use of reduced order models (ROMs) as a substitute for finite element analysis (FEA) solvers enables ship designers to cheaply evaluate many different configurations, only utilizing expensive FEA solvers to validate the most promising ones. Moreover, developers can leverage ROMs with optimization algorithms to extensively explore large parametric domains with minimal supervision [2].

However, the initial formulation of the optimization problem can potentially limit the procedure’s effectiveness because the problem’s size must remain manageable for the purpose of optimization. This restriction poses a challenge even for expert designers, who might select decision variables that are unable to represent the optimal allocation of structural mass in new configurations.

To address this complication, we propose a data-driven reparameterization method that leverages both ROMs and the solutions of a series of subproblems to generate effective parameterizations for the mass optimization of cruise ships, given industry-standard structural constraints [1]. We integrate this technique into an existing optimization pipeline that is used by an Italian shipbuilding company called Fincantieri.

Optimization Pipeline

In the early design phase of a ship, the ship’s geometry is fixed and engineers must select the thickness of primary structural elements like decks, bulkheads, and girders. They then employ FEA to validate potential configurations under extreme wave load conditions; doing so retrieves the stress tensors of the model’s shell elements and post-processes them to compute the yielding and buckling state according to existing criteria.

Designers aim to simultaneously minimize a ship’s total mass and the number of failing elements. Subsequent steps in the creation process eventually apply more involved solutions, such as additional local stiffeners. Along with mass and the number of yielded and buckled elements, an FEA simulation’s quantities of interest (QoIs) are vertical deflection and vertical center of gravity. Minimization of mass conflicts with all of these QoIs and requires careful analysis of the tradeoffs.

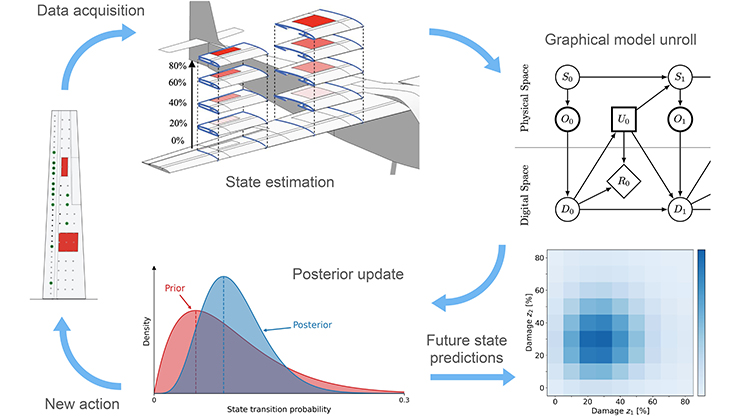

Figure 1 demonstrates our optimization pipeline, which is currently in use by Fincantieri. The utilization of ROMs rather than FEA streamlines the early design phase, and the integration of a data-driven reparameterization procedure refines the optimization problem with minimal effort. We implement the ROMs via non-intrusive proper orthogonal decomposition coupled with Gaussian process regression (GPR) for the retrieval of the stress fields, from which we compute the yielding and buckling states.

![<strong>Figure 1.</strong> The optimization pipeline, from initial model to an optimal ship hull. The reduced order models (ROMs) enable the many optimization steps and automatic refinement of the problem’s formulation. Figure courtesy of [1] and the authors.](/media/15kd5uzw/figure1.jpg)

To obtain a global view of the model’s current behavior, we approximate the Pareto frontier with a genetic algorithm and an infill criterion that is based on the GPR’s correlation estimation. The designers then analyze the Pareto frontier to establish acceptable thresholds for the QoIs and make strategic decisions about the project.

We employ Bayesian optimization to optimize the total mass, which is penalized by the violation of the other QoI thresholds (i.e., vertical deflection and the number of yielded and buckled elements). Extending this classic algorithm ensures that it can handle the discrete domain and take advantage of linear inequalities in the formulation. When the optimization can no longer identify new candidates for FEA validation, users can either accept the best validated hull or refine the optimization problem.

Reparameterization

The assignment of a decision variable to control the thickness of a group of shells in a ship's mesh is a core part of the optimization problem. If the elements that are controlled by this variable show very different structural responses, the resulting configuration might be inefficient. For instance, elements that are subject to low tensions satisfy the structural constraints with low values of thickness, while thicker steel should be reserved for elements that sustain higher tensions.

Even experienced designers struggle to guess the effective assignment of decision variables to elements without resorting to FEA simulations. However, ROMs enable the retrieval of the responses—in terms of QoIs—of each element as the thickness configuration changes. Such results facilitate the search for a different assignment, thus reducing the mass and containing the insurgence of yielding and buckling. We must also constrain the assignment to guarantee that elements of the same patch (e.g., a physical steel sheet that is approximately 2.5 meters by 15 meters) are assigned to the same variable.

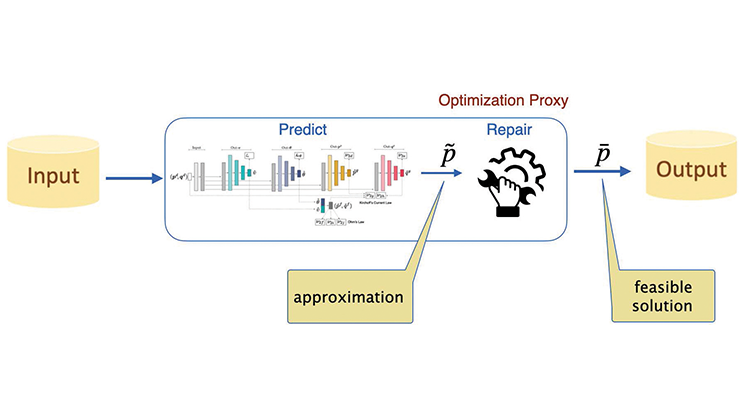

Figure 2 illustrates the reparameterization of a deck with six patches, beginning with the optimal thickness from Bayesian optimization. After the evaluation of other possible thickness values, an optimization subproblem finds an assignment of two different values that minimize the penalized mass. We use the solution values as labels when assigning the patches’ elements to two distinct decision variables, thus adapting the global problem formulation to the emerging stress distribution.

![<strong>Figure 2.</strong> Reparameterization of a ship deck that is comprised of six patches. <strong>2a.</strong> The initial optimum, courtesy of Bayesian optimization (BO). <strong>2b.</strong> Evaluation of other possible thickness values. <strong>2c.</strong> Clustering of patches with optimization. <strong>2d.</strong> The new assignment of patches to decision variables via optimized clustering. Figure adapted from [1] and courtesy of the authors.](/media/in5lq3iu/figure2.jpg)

The sequence of refined parameterizations is hierarchical, in that we can still construct all previous thickness configurations in the latest parametric domain. This property allows us to leverage the previous high-fidelity database—with minimal additional sampling of the new domain—to build updated ROMs and restart the pipeline.

Case Study

We evaluate our optimization pipeline on the structural optimization of a full ship, for which an FEA simulation takes seven minutes and a single ROM query is about 0.5 seconds — resulting in an approximately 840x speedup. Here, we compare three different approaches: (i) iterative reparameterization of a base model with 10 parameters, up to 40 parameters; (ii) one-shot reparameterization of the base model up to 40 parameters; and (iii) a designer-provided model with 40 parameters. We perform multi-objective and mass optimization for each parameterization.

Figure 3 depicts the evolution of the high-fidelity optimum, expressed as the gap from the lower bound of the mass that is controlled by the parameters. The reparameterization procedure enables the 16-parameter model and the one-shot technique to surpass the designer model, which stops producing new optimum candidates earlier than the other alternatives. The iterative method ultimately achieves a better optimum than the one-shot approach, obtaining 27 parameters after the second reparameterization. The final iteration, which reached 40 parameters, yields diminishing returns.

![<strong>Figure 3.</strong> Evolution of the high-fidelity optimum for different parameterization approaches of a full ship. Each color corresponds to a different parameterization. Figure adapted from [1] and courtesy of the authors.](/media/bvdkicir/figure3.jpg)

Outlook

We present a new parameterization refinement procedure—which leverages ROMs and the resolution of optimization subproblems—to help structural optimization scenarios achieve better optima. Our procedure was integrated into an existing automated optimization pipeline—currently in use by Fincantieri—for the initial design phase of cruise ships. We evaluated the updated pipeline with different approaches to model refinement, ultimately demonstrating that the reparameterized models achieve better performance than a model with the same number of parameters that was generated by expert designers. These results suggest that the optimization pipeline could streamline the early design phase for cruise ships—and possibly other structures—due to its high level of automation and minimal need for user intervention.

Marco Tezzele delivered a minisymposium presentation on this research at the 2025 SIAM Conference on Computational Science and Engineering, which took place in Fort Worth, Texas, earlier this year.

References

[1] Fabris, L., Tezzele, M., Busiello, C., Sicchiero, M., & Rozza, G. (2025). Data-driven parameterization refinement for the structural optimization of cruise ship hulls. Int. J. Num. Meth. Eng., 126(24), e70201.

[2] Tezzele, M., Fabris, L., Sidari, M., Sicchiero, M., & Rozza, G. (2023). A multifidelity approach coupling parameter space reduction and nonintrusive POD with application to structural optimization of passenger ship hulls. Int. J. Num. Meth. Eng., 124(5), 1193-1210.

About the Authors

Lorenzo Fabris

Ph.D. student, International School for Advanced Studies

Lorenzo Fabris is a Ph.D. student at SISSA mathLab of the International School for Advanced Studies (SISSA) in Italy. He holds an M.Sc. in information engineering from the University of Padua and a master’s in high-performance computing from SISSA.

Marco Tezzele

Assistant professor, Emory University

Marco Tezzele is an assistant professor in the Department of Mathematics at Emory University and a member of Emory’s Scientific Computing Group. His research interests include digital twins, data-driven reduced order methods, parameter space reduction techniques, scientific machine learning, and structural optimization in naval engineering.

Ciro Busiello

Head of Basic Structural Design, Fincantieri

Ciro Busiello is head of the Basic Structural Design Department at the Italian shipbuilding company Fincantieri, where he is responsible for the structural design of hulls on passenger ships. He holds an M.Sc. in naval architecture and marine engineering. Busiello’s research interests include structural concepts and design methodologies, preliminary design of passenger ships, linear static finite element analysis, fatigue, and buckling assessment.

Mauro Sicchiero

Lead specialist in hull structural design, Fincantieri

Mauro Sicchiero is a lead specialist in hull structural design in the Structural Design Department at Italian shipbuilding company Fincantieri, with two decades of experience in the structural design and fabrication of roll-on/roll-off ships and cruise ships. He was a member of the International Ship and Offshore Structures Congress from 2012 to 2025. Sicchiero’s recent research interests include structural optimization, the design of floating offshore wind turbines, and the integration of alternative fuel systems such as liquefied natural gas and liquid hydrogen.

Gianluigi Rozza

Full professor, International School for Advanced Studies

Gianluigi Rozza is a full professor of numerical analysis and scientific computing at the International School for Advanced Studies (SISSA) in Italy. He is coordinator of both SISSA mathLab and the Director’s Delegate for Innovation, Valorization of Research, and Technology Transfer. Rozza is also the scientific director of SISSA’s FAST Computing startup.

Related Reading

Stay Up-to-Date with Email Alerts

Sign up for our monthly newsletter and emails about other topics of your choosing.