The Making of Flat Surfaces: From Leaves to Batteries

Flat surfaces, or reasonable approximations thereof, are all around us: on tables, computer screens, paper, and microchips. Most of these surfaces are manmade via a considerable amount of manufacturing effort.

Although a flat shape seems geometrically simple, its ordered nature implies low entropy and therefore demands explanation. To achieve flatness in a structure, we expend energy—either during the manufacturing process or throughout its lifetime—to maintain a nonequilibrium state. Consequently, the fabrication of flat surfaces typically involves energy-intensive processes such as pressing, polishing, heating, vacuum treatment, or the use of clean rooms.

In contrast, living systems—like leaves—develop flat shapes in noisy and sometimes unpredictable environments. They accomplish this feat through continuous sensing and regulation, actively adjusting their structure to remain flat. A leaf's ability to maintain flatness amid perturbations offers insights into the prospective design of self-regulating synthetic systems.

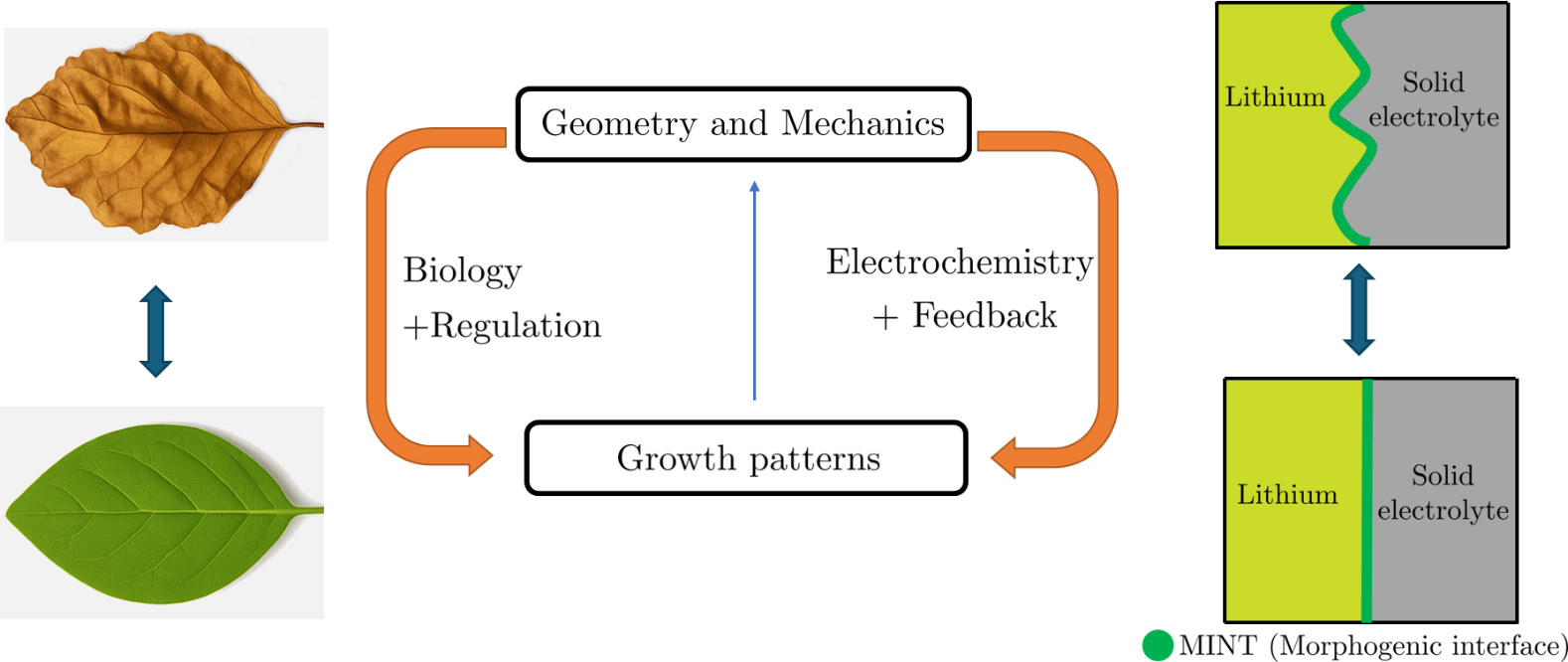

This type of biological capability demonstrates the power and potential of self-regulating, shape-controlling systems that can grow robustly without constant external control. Here, I will illustrate the way in which principles from the physics of leaf growth can inform the design of flat, stable electrochemical interfaces in next-generation solid-state batteries, which are required for high-energy-density applications such as electric vehicles and aircraft.

Morphogenesis in Leaves: A Case Study in Shape Control

To emulate biological systems, we must understand the physical principles that underlie shape control in living matter. Leaves are ideal systems for doing so, since they begin as small bulges on the shoot apical meristem and grow into broad, flat laminae that comprise billions of cells. This transformation is nontrivial; without control, leaves would warp due to variations in growth and environmental stress.

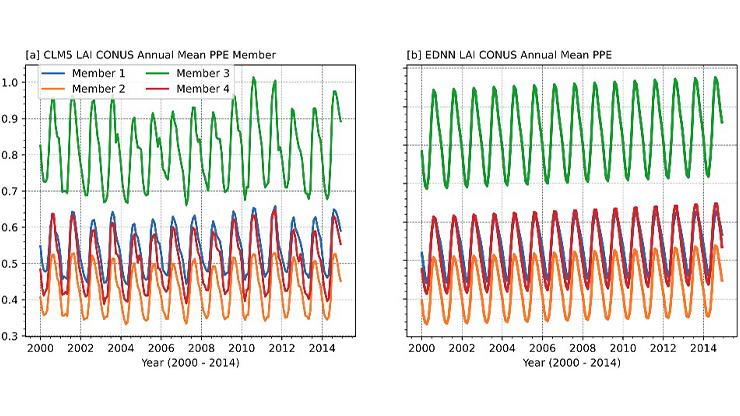

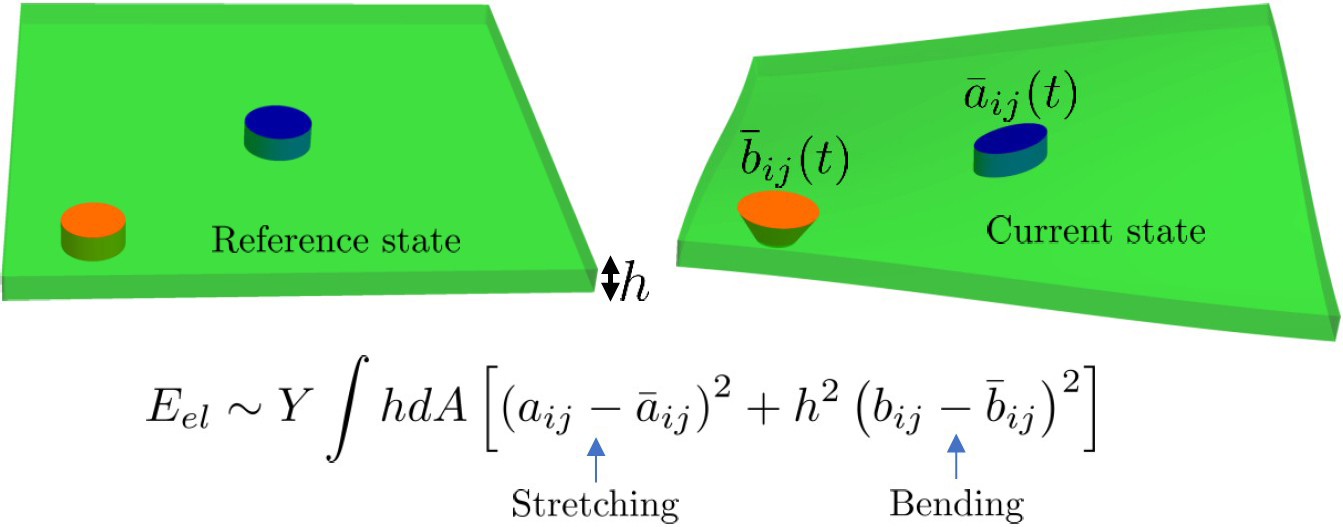

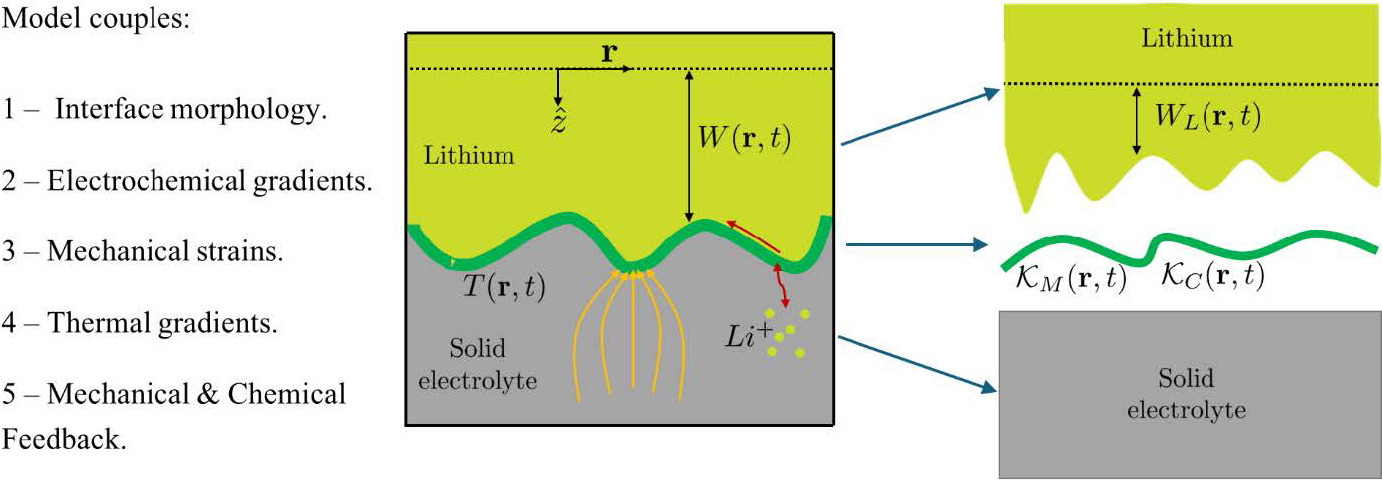

We model leaves as active, growing thin elastic shells [1]. A surface metric tensor \(a_{ij}\) and curvature tensor \(b_{ij}\) describe their geometry, while \(\bar{a}_{ij}(t)\) and \(\bar{b}_{ij}(t)\) denote leaves’ preferred (or rest) configurations. In this context, we model growth as a time evolution of the rest metric and natural curvature tensors, encoding in-plane and out-of-plane changes respectively (see Figure 1).

Growing cells push against their neighbors, causing stress and altering the tissue’s curvature. These mechanical signals, which are sensed by stress-sensitive microtubules, modulate the cellular growth rates. In this way, curvature and stress both serve as feedback signals that guide the tissue toward its flat target state.

Feedback can be local (based only on nearby cues) or long-range (mediated by mechanical and chemical signals that propagate across the leaf). Our calculations show that local feedback alone cannot sufficiently suppress long-wavelength instabilities, which would result in large-scale wrinkling. But when we include long-range feedback, the model stabilizes to a flat configuration and matches observed experimental scaling of growth rate fluctuations with patch size.

Interface Morphodynamics in Solid-state Batteries

So, what does this have to do with batteries? Like leaves, solid-state lithium batteries rely on flat surfaces for proper function. The lithium-electrolyte interface must remain smooth during the plating and stripping processes to avoid instabilities such as void formation and dendrite growth, which can degrade battery life and cause internal shorts.

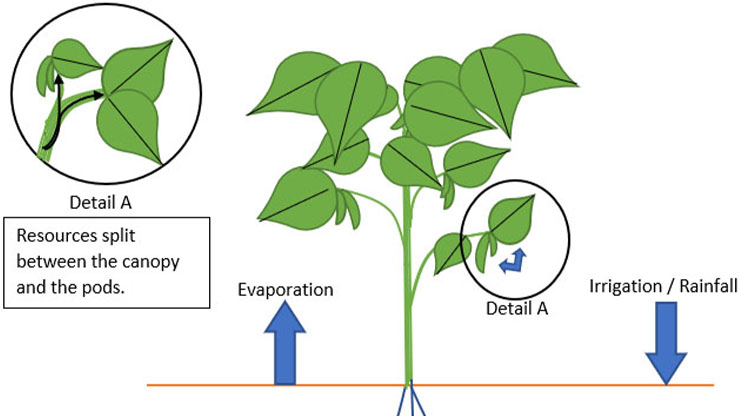

Inspired by leaf morphogenesis, we seek to regulate the battery interface via morphogenetic interfaces (MINTs): bio-inspired layers that sense and respond to morphological changes in order to maintain flatness (see Figure 2). This idea—inspired by work that was funded by the Defense Advanced Research Projects Agency—leverages the same feedback-driven logic as in biological growth (i.e., morphogenesis).

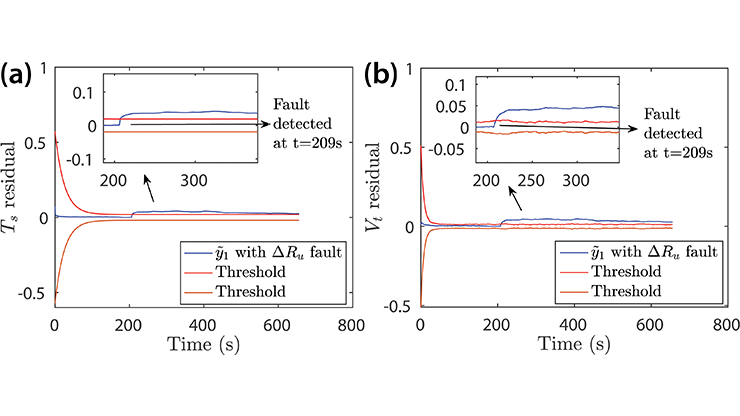

To model this concept, we developed a reduced-order continuum model that couples electrochemical kinetics (e.g., the Butler-Volmer equation), mechanical deformation (e.g., creep and stress), and interface morphology [2] (see Figure 3). We found that interface regions with higher curvature exhibit enhanced reaction rates due to electric field intensification and heightened mechanical pressure; in turn, these enhanced rates increase the curvature even more and destabilize the flat state. Such morphological instabilities can lead to voids and dendrites.

MINTs counter this effect by adaptively increasing local resistance to lithium deposition in protruding regions, essentially applying a negative feedback loop. As with leaves, local feedback cannot sufficiently stabilize the interface — doing so also requires long-range feedback through diffusive signaling.

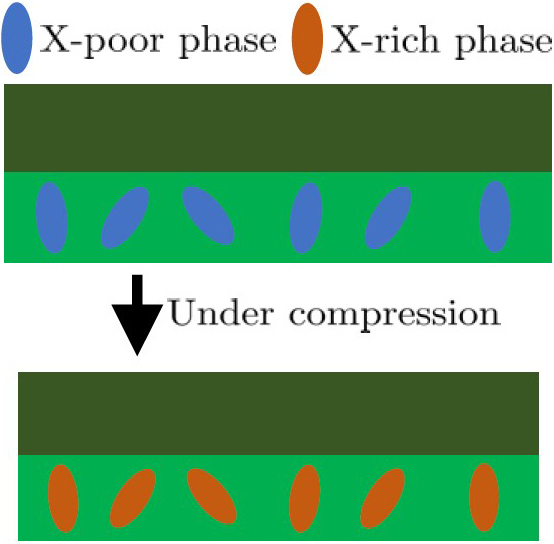

Our work suggests that it is possible to generate these signals from inclusions that undergo curvature-sensitive phase transitions (e.g., from X-rich to X-poor states in response to increased pressure) that alter local ion concentration, thus acting as morphology sensors and growth actuators to realize long-range negative feedback loops (see Figure 4).

Concluding Thoughts

Controlling shape is a universal challenge that arises in many situations, from living leaves to engineered batteries. Our research explores the capability of feedback—especially long-range and shape-responsive feedback—to regulate and stabilize complex, evolving surfaces. This approach blends continuum mechanics and control theory in a new framework for materials design, where the system monitors its own state relative to a desired configuration and adjusts accordingly. Such strategies bring us one step closer to fabrication through regulation, where structure emerges not by forceful constraint but by smart, responsive growth.

Our study is ongoing, but it already points toward a future where self-regulating materials could grow themselves into shapes: robustly, scalably, and with minimal supervision. Feedback-driven morphodynamics offers a powerful paradigm for building the future in biomedicine, energy storage, autonomous manufacturing, and beyond.

Salem Al Mosleh delivered a minisymposium presentation about this research at the 2025 SIAM Conference on Computational Science and Engineering, which took place earlier this year in Fort Worth, Texas.

Acknowledgments: This work was supported in part by the Defense Advanced Research Projects Agency (DARPA) under contract no. HR00112220032. The results contained herein are those of the author and should not be interpreted as necessarily representing the official policies or endorsements, either expressed or implied, of DARPA or the U.S. government. This research was also supported in part by grant NSF PHY-2309135 and the Gordon and Betty Moore Foundation grant no. 2919.02 to the Kavli Institute for Theoretical Physics.

References

[1] Al-Mosleh, S., & Mahadevan, L. (2023). How to grow a flat leaf. Phys. Rev. Lett., 131(9), 098401.

[2] Mosleh, S., Annevelink, E., Viswanathan, V., & Mahadevan, L. (2025). Controlling moving interfaces in solid-state batteries. Proc. R. Soc. A, 481(2315), 20240785.

About the Author

Salem Al Mosleh

Assistant professor, University of Maryland Eastern Shore

Salem Al Mosleh is an assistant professor of physics at the University of Maryland Eastern Shore. His research explores soft matter, biological physics, and electrochemical interfaces, with a focus on feedback-driven morphodynamics.

Stay Up-to-Date with Email Alerts

Sign up for our monthly newsletter and emails about other topics of your choosing.